Biogas calculator

Success stories

Download our catalog

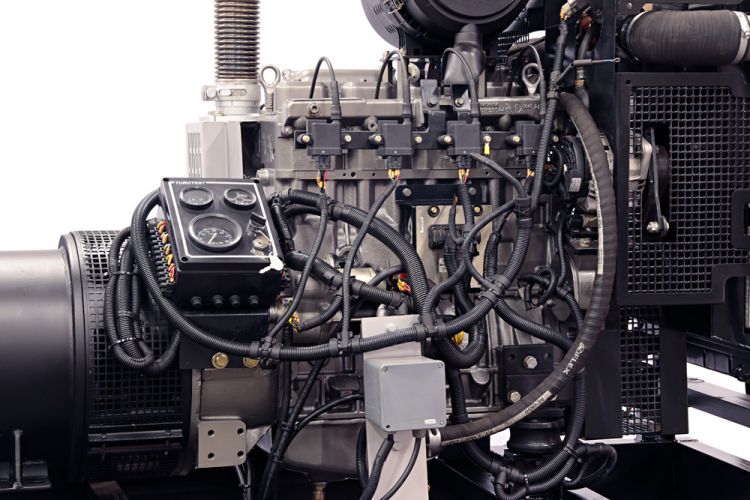

GKG – Biogas Generator Group (Agribusiness)

Germek, a Brazilian company with 40 years’ experience and a sustainable spirit, has developed a line of products that provides our customers with a solution that minimizes the environmental impacts generated by their production process and also helps to make their results even more profitable.

Our line of GKG generator sets can be applied to different niches found in agribusiness and their production processes have great potential for generating biogas or biomethane, so we find this source of clean fuel in pig farming, poultry farming and livestock farming.

In this application model, we have a solution for clean energy generation. The GKG Biogas Generator Sets operate from the residual “Biogas or Biomethane” from the decomposition of animal waste, so this gas is a rich fuel with percentages of 60 to 80% CH4 (Methane Gas), which varies according to the conditions found in the field and which, after passing through a meticulous filtering system to remove H²S (Hydrogen Sulfide Gas), which is highly aggressive and harmful to the environment. test cypionate cycle operation of the Engine, gives the producer another source of income to contribute to the success of his business.

We have developed a complementary product that is very special in this solution: the mineral-based GKG Filter enables perfect retention of the hydrogen sulphide gas that resides in biogas from animal waste, so our GKG Biogas Generator Sets offer a long service life and greater profitability for the project.

We use high technology to develop our products, so the engines used in the GKG Biogas Generator Sets are all originally manufactured to use gas fuel. We do not transform diesel engines into gas engines, as this adaptation does not guarantee perfect operation for the equipment and, when added to an inefficient or non-existent filtering system, results in a very short engine life. We already have GKG Biogas Generating Sets in operation for more than 6 years, always running on a “Continuous” basis (more than 8 hours a day) without the need for Corrective Maintenance (Component Breakdown/Defect), only Preventive Maintenance (Replacement of Perishables, Filters, Fluids, Battery according to our Maintenance plan).

| BIOGAS MODELS ANIMAL WASTE | STANDBY (KVA) 60HZ | PRIME (KVA) 60HZ | CONTINUOUS (KVA) 60HZ | FINAME CODE | MORE FOOD CODE |

| GKG – 50 | 60 | 50 | 43 | – | – |

| GKG – 112 | 125 | 112 | 90 | 3472586 | M008A371 |

| GKG – 120 | 150 | 135 | 120 | 3472586 | M008A371 |

| GKG – 250 | 300 | 250 | 220 | – | – |

| GKG – 350 | 400 | 350 | 320 | 3472586 | M008A371 |

| GKG – 425 | 500 | 425 | 362 | – | – |

This equipment can be applied to different types of Clean Energy Generation solutions with GKG Biogas or Biomethane equipment, so we can develop a project that meets your characteristics in the field, providing the best cost-benefit ratio in terms of investment, see some examples below:

Island Model Biogas Clean Energy Generation Project – In this format, the equipment(s) will be installed to meet one or more of the different “Loads” available at the customer’s plant. This type of installation should only be carried out in specific cases, as its return on investment “Payback” takes longer due to the fact that it uses part of the installed capacity of the GKG Biogas Generator Group, which is due to the need for reserve power to start the Loads. In this project format, the equipment is usually presented with a Manual Operation Control.

Biogas Clean Energy Generation Project Base Load Model – This project model allows for a more efficient solution than the “Island model” because it will use practically the full capacity of the equipment employed, so the GKG Biogas or Biomethane Generating Sets will be installed operating interconnected and in parallel with the secondary of the utility’s transformer, thus taking over part of the loads installed at the customer’s plant. In this project model, the equipment will always be undersized in relation to the customer’s transformer and the loads installed in their plant. This project model requires a larger investment than the “Island model”, but it offers a better payback. This project model uses state-of-the-art automation that enables automatic operation and protection of the system’s equipment and users.

Biogas Clean Energy Generation Project Model Plant – In this application, the project presents the best cost-benefit conditions, as it uses 100% of the capacity of the Biogas or Biomethane Clean Energy Generation Plant, which, depending on the sizing and characteristics available in the field, can also achieve the best financial return, In this way, the equipment will be connected in parallel to the utility grid and will export the energy generated by the GKG Biogas or Biomethane Generators to it. This model has a metering clock that will measure the credits generated as a result of this export, enabling the customer to zero out their energy bill with the local utility. This project model also uses state-of-the-art automation that enables automatic operation and protection of the system’s equipment and users.

We have turnkey solutions where, in addition to the GKG Generator Sets or GKG Filters, we also have a technical team trained to specify, design, install and provide preventive/corrective maintenance for the equipment offered, so when you purchase our solutions the equipment will be delivered operating according to the scope purchased.

Our products are duly registered and eligible for the credit facilitation programs available on the market and also subsidized by the government.